GAIA AM

Advanced Milling Improvement and Inline Supervision System

GAIA AM is a cutting-edge software and hardware system designed to transform milling processes. By seamlessly integrating with your machining setup, GAIA AM listens to your milling process in real-time, providing invaluable insights and enhancements for optimal performance.

Quality Assurance in Production: A Strategic Necessity

In a mass production environment, the quest for quality is pivotal, influencing both production ramp-up and ongoing execution. Quality assurance is not just about product excellence; it's a strategic necessity impacting customer satisfaction, brand reputation, and operational efficiency. During production ramp-up, ensuring meticulous quality becomes crucial to avoid cascading effects on large product batches. In ongoing execution, maintaining consistent quality is vital for brand integrity and competitiveness.

GAIA AM Bridging Towards Unwavering Quality in Production

In this challenging landscape, inline supervision emerges as the key to unwavering quality in mass production. GAIA AM, an advanced solution, stands as the linchpin in this process. By seamlessly integrating into production, GAIA AM identifies and addresses potential issues in real time, ensuring each product adheres to the highest quality standards. In the vast scale of mass production, GAIA AM becomes the indispensable link, guaranteeing top-tier quality from production ramp-up to ongoing execution.

Up to 90% Reduced Inspection Time

Streamlining inspection processes and saving valuable time.

Up to 75% Scrap Material Reduction

Minimizing waste and optimizing material usage.

100% Quality Assurance

Ensuring unparalleled quality by eliminating defects and inconsistencies.

100% Autonomous Process Execution

Fully automating milling processes for consistent results.

Improved Sustainability

Optimizing processes and reducing waste for enhanced sustainability.

Increased Machine Uptime & Tool Life

Proactive diagnostics and maintenance for maximized productivity. Intelligent supervision to extend the lifespan of tools.

HOW IT WORKS?

GAIA AM becomes the indispensable link, guaranteeing top-tier quality from production ramp-up to ongoing execution.

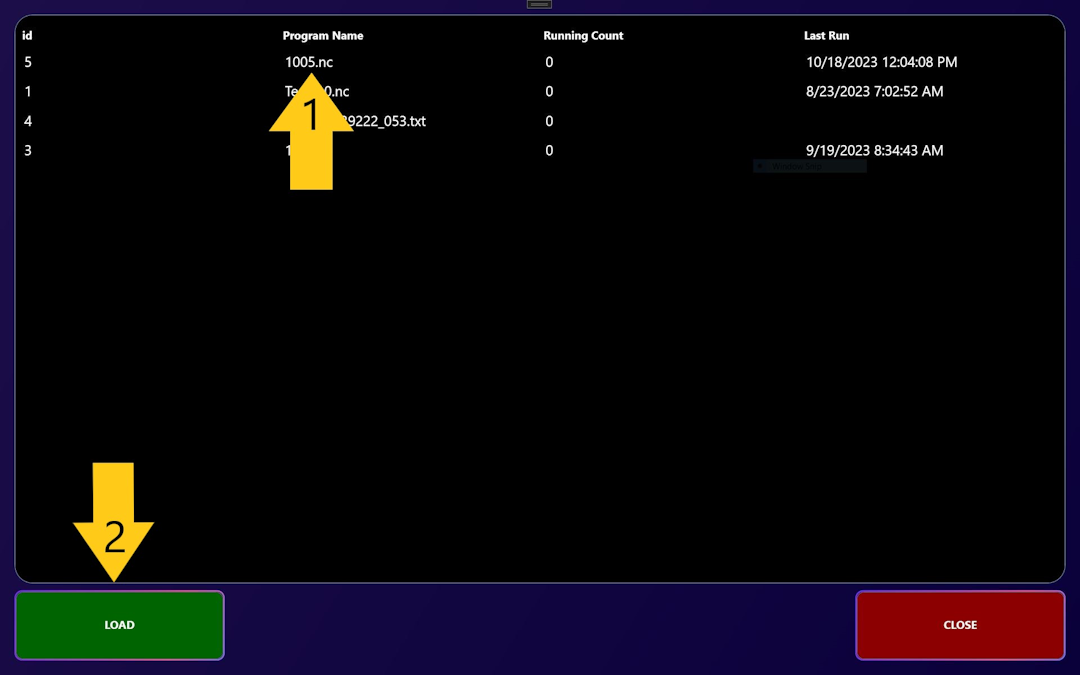

Upload Your G-code to GAIA AM

Experience a seamless integration with GAIA AM by uploading your G-code via the userfriendly interface or internal network.

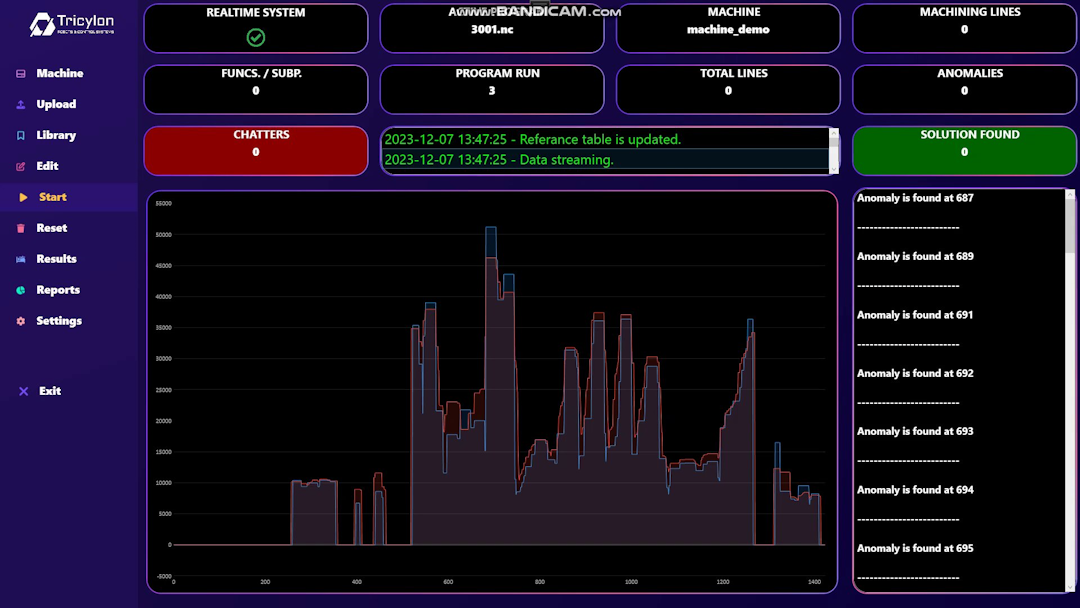

Milling Code Analysis

With a simple press of the start button, GAIA AM springs into action. The system meticulously analyzes your machining code, employing advanced reverse engineering techniques to identify and extract crucial milling parameters.

Analyzes Sound and Identifies Changes and Abnormalities

GAIA AM doesn't just rely on code; it listens to your milling process. By analysing sound patterns, the system identifies changes and abnormalities in real-time. This proactive approach allows GAIA AM to detect potential issues before they impact the final product, ensuring a smooth production.

Chatter Detection and Optimization

Chatter in milling processes can be a hindrance to quality and efficiency. GAIA AM is equipped with automatic feature analysis to detect and handle chatter effectively. The system suggests optimizations on-the-fly, ensuring that your milling operations remain free from disruptions and produce superior operations.

Workpiece Feature Identification & Process Speed Improvements

As the milling process concludes, GAIA AM doesn't stop working. It goes beyond the basics and identifies features that can be further optimized for speed. This post-milling analysis guarantees that each operation is continually refined, maximizing efficiency, and reducing production time.

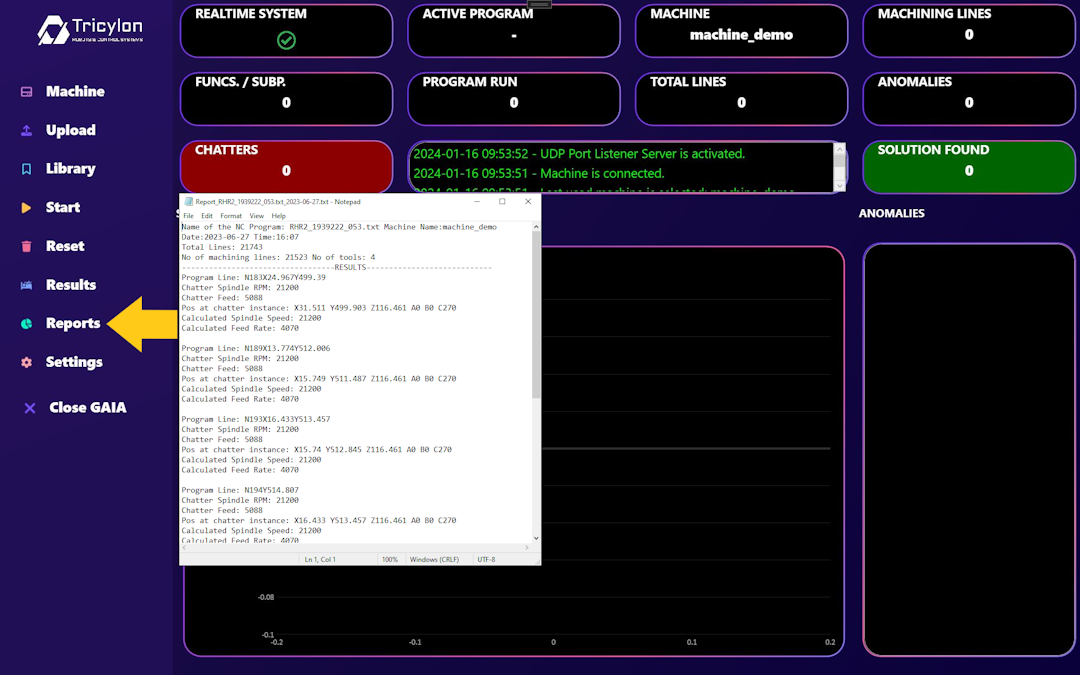

Automatic Reports for Quality Traceability

GAIA AM takes quality assurance to the next level by automatically generating comprehensive reports. These reports not only serve as a record of the milling process but also provide a detailed overview of quality parameters. This automatic reporting feature enhances traceability, making it easy to track and verify the quality of each milled component throughout the value chain.